Replacement Sharpening Stone One Size

Replacement Sharpening Stone

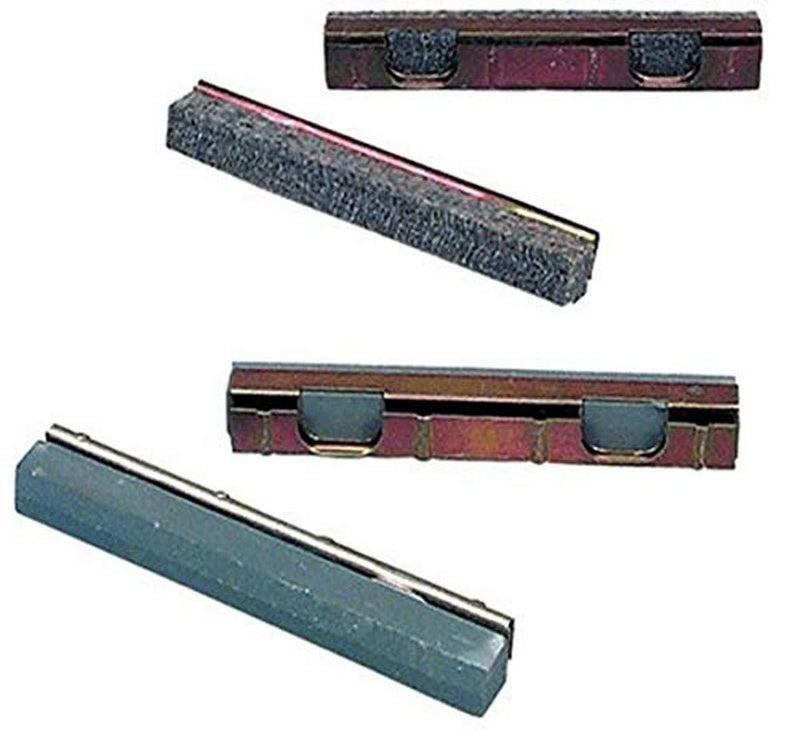

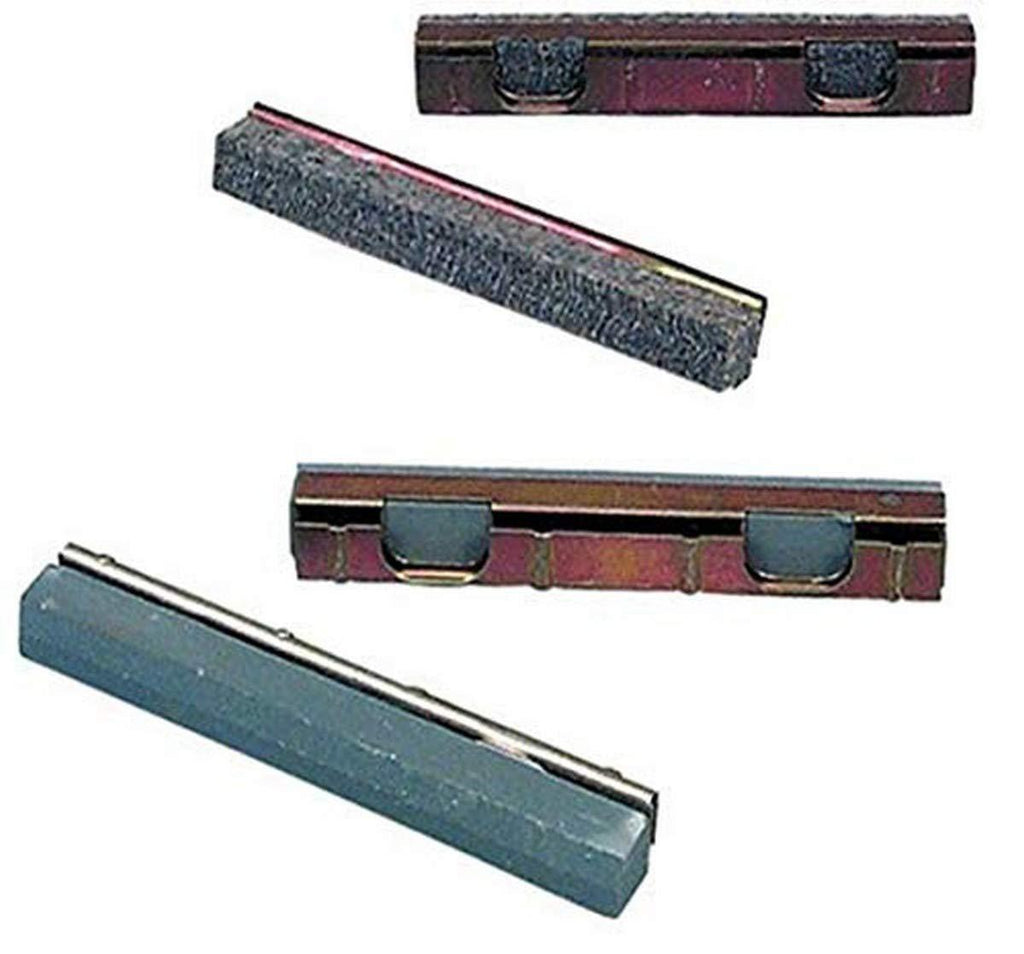

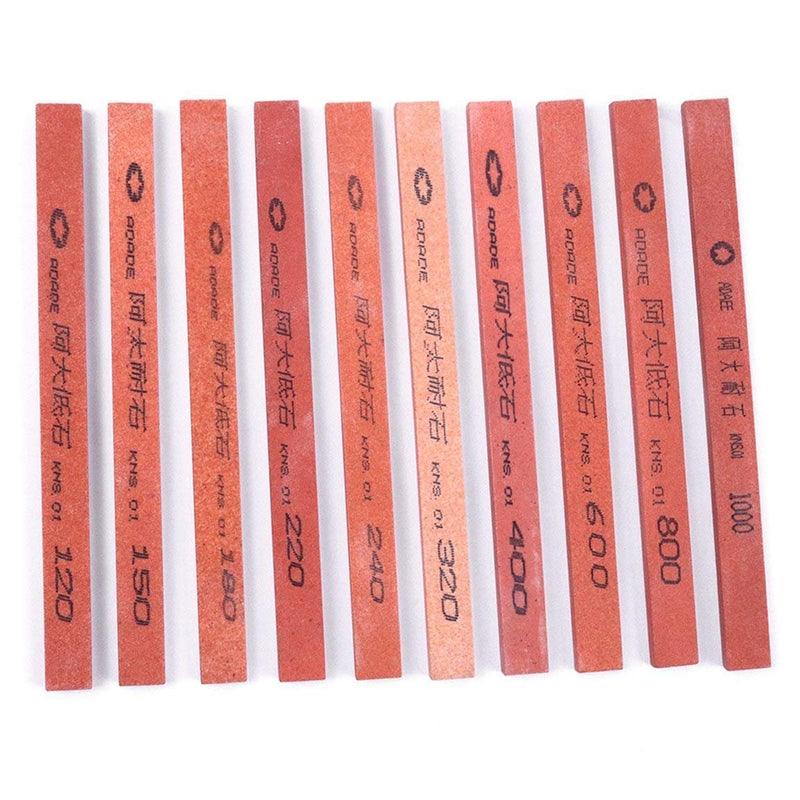

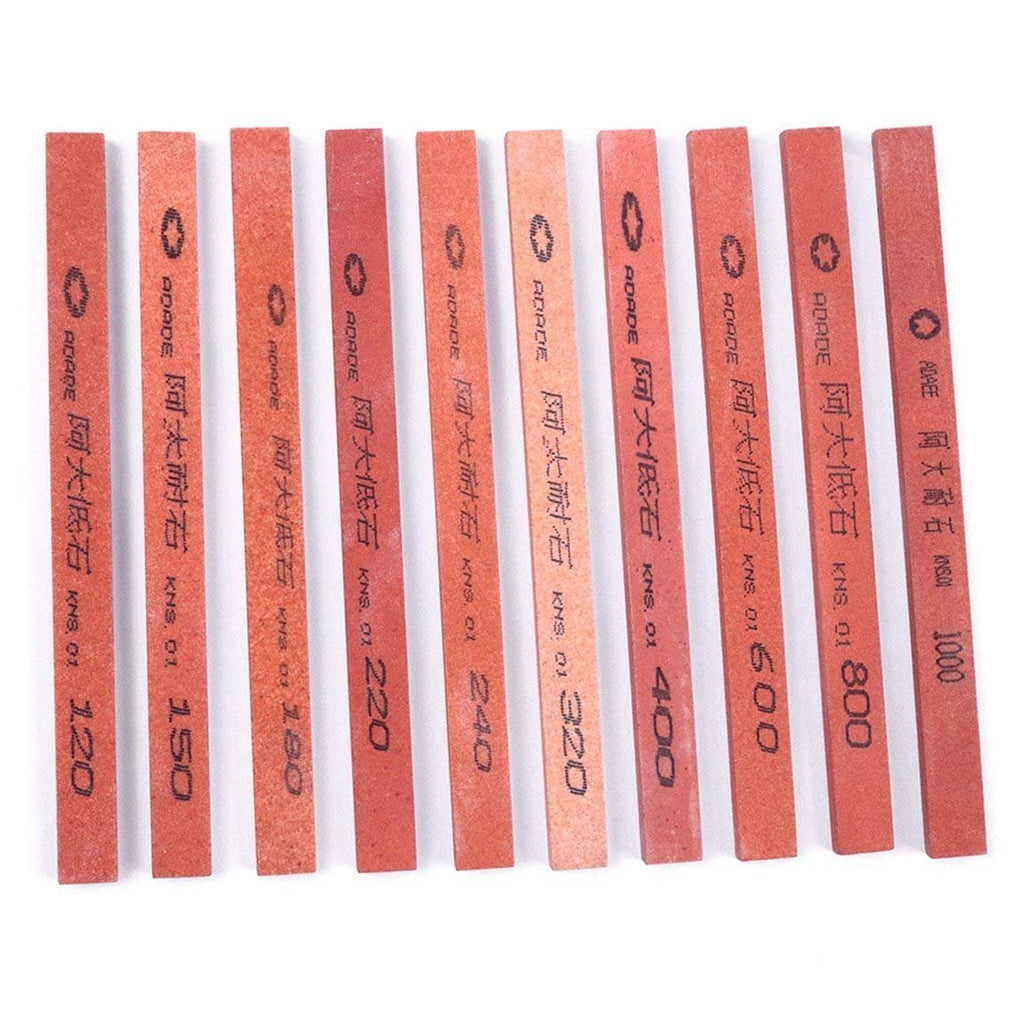

Size:One Size The Norton JM6 Crystolon medium-grit replacement oilstone for the IM313 sharpening system is made of 150-grit silicon carbide, suitable for sharpening and maintaining cutting edges; it sharpens to moderate tolerances with minimal loading when it is more important to sharpen the blade quickly than to produce a fine cutting edge. The stone is prefilled with oil to save time and eliminate the need to presoak it prior to use. The oil prevents metal from bonding with the abrasive surface by flushing away dislodged abrasive and metal chips. This oilstone is commonly used to replace a stone in the Norton IM313 sharpening system, or as a bench stone, to restore cutting edges on straight-edged tools such as chisels, knives, plane blades, and precision instruments. This silicon carbide stone is fast-cutting, and offers effective sharpening even under light pressure. It is created by grading silicon carbide to a consistent particle size and blending it with bonding agents. It is then molded and surface-finished. Unusually large dimensions of 1/2 x 11-1/2 x 2-1/2 inches (H x W x D) make this stone suitable for bench use. (H is height, the vertical distance from lowest to highest point; W is width, the horizontal distance from left to right; D is depth, the horizontal distance from front to back.) Like most oilstones, it is harder and more durable than a waterstone. It conforms to the American National Standards Institute (ANSI) abrasive grit standards. Sharpening stones, or whetstones, are abrasive surfaces used to sharpen and hone the edges of steel cutting implements, such as chisels, knives, scissors, hand scrapers, and plane blades. Sharpening is the process of creating or re-establishing a cutting edge by grinding away portions of the metal to adjust the angle of the edge and reform the shape. Honing removes small imperfections. Stones can be flat, for working flat edges, or shaped, for edges that are more complex. Sharpening stones are made of natural or synthetic materials that range from softer to harder, and are categorized by the size of their abrasive particles, known as grit. A stone with a coarser grit is used when more metal needs to be removed (e.g., when sharpening a nicked or very dull blade); the stone with the finest grit produces the sharpest edge. Where numbers are assigned to specify grit, they range from coarser grit (low) to finer grit (high). Some sharpening stones are designed for use with a lubricating liquid, some can be used dry, and others can be used either wet or dry. When used with lubricating liquid, a sharpening stone can be called a waterstone or an oilstone, based on the lubricant required. Norton Abrasives manufactures sanding, grinding, and polishing abrasives, and has been located in the United States since 1885. Norton, now a brand of Saint-Gobain, meets ISO 9000 and 14001 certification for quality and environmental management standards. From the Manufacturer JM6 Medium Grit Crystolon@ IM313 Replacement Stones are Bench Oilstones made with fast cutting man-made abrasives for quick edge sharpening. Use to sharpen dull edges quickly and upgrade the finish left by a Coarse Crystolon stone. Norton Crystolon@ oilstones are manufactured using a proprietary process that impregnates them with a petroleum based product that allows the lubrication used during the sharpening process to stay on the stone's surface. As a result, the metal from the object being sharpened and small pieces of abrasive that break off the stone become suspended in the lubricant. This prevents these materials from imbedding into the sharpening stone's surface, keeping it free cutting and making it easy to keep its surface clean.

Product Features

- Crafted from the highest quality materials

- Built for performance and durability

- Made in United States

Buy with confidence as this product comes with 18 months full local warranty in Australia & New Zealand (unless otherwise stated in the overview).

This product also comes with the benefits of the CocoonPower Warranty. For further details please read our Warranty Guidelines.

You can also purchase 3 Year Extended Care. If you are interested please see our Extended Care Information.